The landscape of additive manufacturing is continually evolving, with breakthroughs pushing the boundaries of what’s possible. Recent advancements in liquid printing techniques are poised to significantly impact various industries, offering unprecedented speed, design freedom, and material versatility.

Rapid Liquid Printing and its Potential

Rapid Liquid Printing (RLP) represents a paradigm shift in 3D printing technology. Unlike traditional methods that rely on layer-by-layer deposition in a solid support structure, RLP suspends the printing material within a gel medium. This allows for the creation of complex, self-supporting structures without the need for extensive support removal post-printing. The implications of this are vast.

One of the most significant benefits of RLP is its ability to produce parts at remarkable speeds. By eliminating the constraints of layer-by-layer fabrication, RLP can generate objects much faster than conventional 3D printing methods. This enhanced speed is particularly advantageous for rapid prototyping, customized manufacturing, and on-demand production of large-scale components.

Furthermore, RLP unlocks new possibilities in terms of design freedom. The absence of support structures enables the creation of intricate geometries, organic shapes, and hollow structures that were previously difficult or impossible to achieve. This opens up exciting avenues for innovation in fields such as architecture, product design, and biomedical engineering, where complex and customized shapes are often required.

The versatility of materials that can be used with RLP is another key advantage. The technology is compatible with a wide range of materials, including elastomers, silicones, and even some types of foams. This allows for the creation of parts with diverse mechanical properties, ranging from flexible and resilient to rigid and durable. The ability to tailor material properties to specific applications further expands the potential of RLP.

MIT’s Contributions to Liquid Printing Innovation

Researchers at MIT have been at the forefront of developing and refining liquid printing techniques. Their work has focused on optimizing the printing process, expanding the range of compatible materials, and exploring novel applications for the technology. MIT’s research has played a crucial role in advancing the field of liquid printing and demonstrating its potential to revolutionize manufacturing.

MIT’s contributions extend beyond the technical aspects of RLP. They have also explored the integration of liquid printing with other manufacturing processes, such as robotics and automation. This integration has the potential to further enhance the speed, efficiency, and scalability of liquid printing. By combining liquid printing with other advanced technologies, MIT is paving the way for a more integrated and automated manufacturing ecosystem.

The research conducted at MIT has also focused on addressing some of the challenges associated with liquid printing. These challenges include controlling the viscosity and stability of the printing material, ensuring accurate deposition of the material, and developing robust post-processing techniques. By overcoming these challenges, MIT is helping to make liquid printing a more reliable and practical manufacturing solution.

In conclusion, rapid liquid printing is a transformative technology with the potential to revolutionize 3D printing. Its enhanced speed, design freedom, and material versatility make it a promising solution for a wide range of applications. As research and development efforts continue to advance the technology, we can expect to see even more innovative applications of RLP emerge in the years to come, transforming industries and pushing the boundaries of manufacturing.

If you are searching about Nanoscale "supersoap" allows liquid 3D structures to be printed within you’ve came to the right place. We have 10 Images about Nanoscale "supersoap" allows liquid 3D structures to be printed within like Rapid Liquid Printing Will Revolutionize 3D Printing | This 3D liquid, New Rapid Liquid Printing technique set to revolutionize 3D printing and also MIT Researchers Present Rapid Liquid Printing – 3D Printing. Read more:

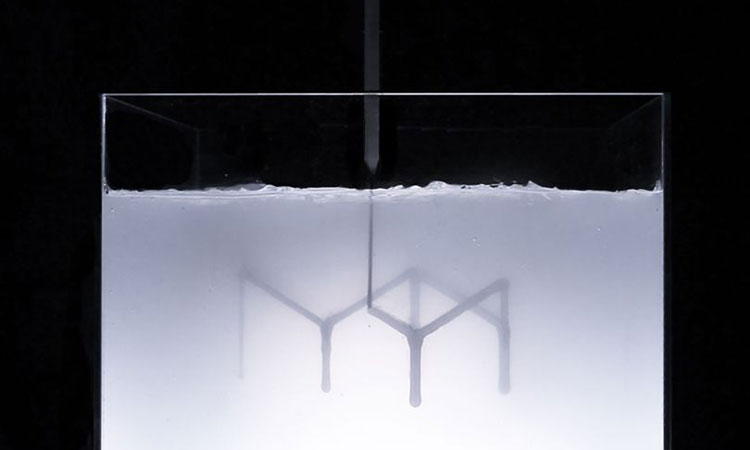

Nanoscale "supersoap" Allows Liquid 3D Structures To Be Printed Within

newatlas.com

Nanoscale "supersoap" allows liquid 3D structures to be printed within …

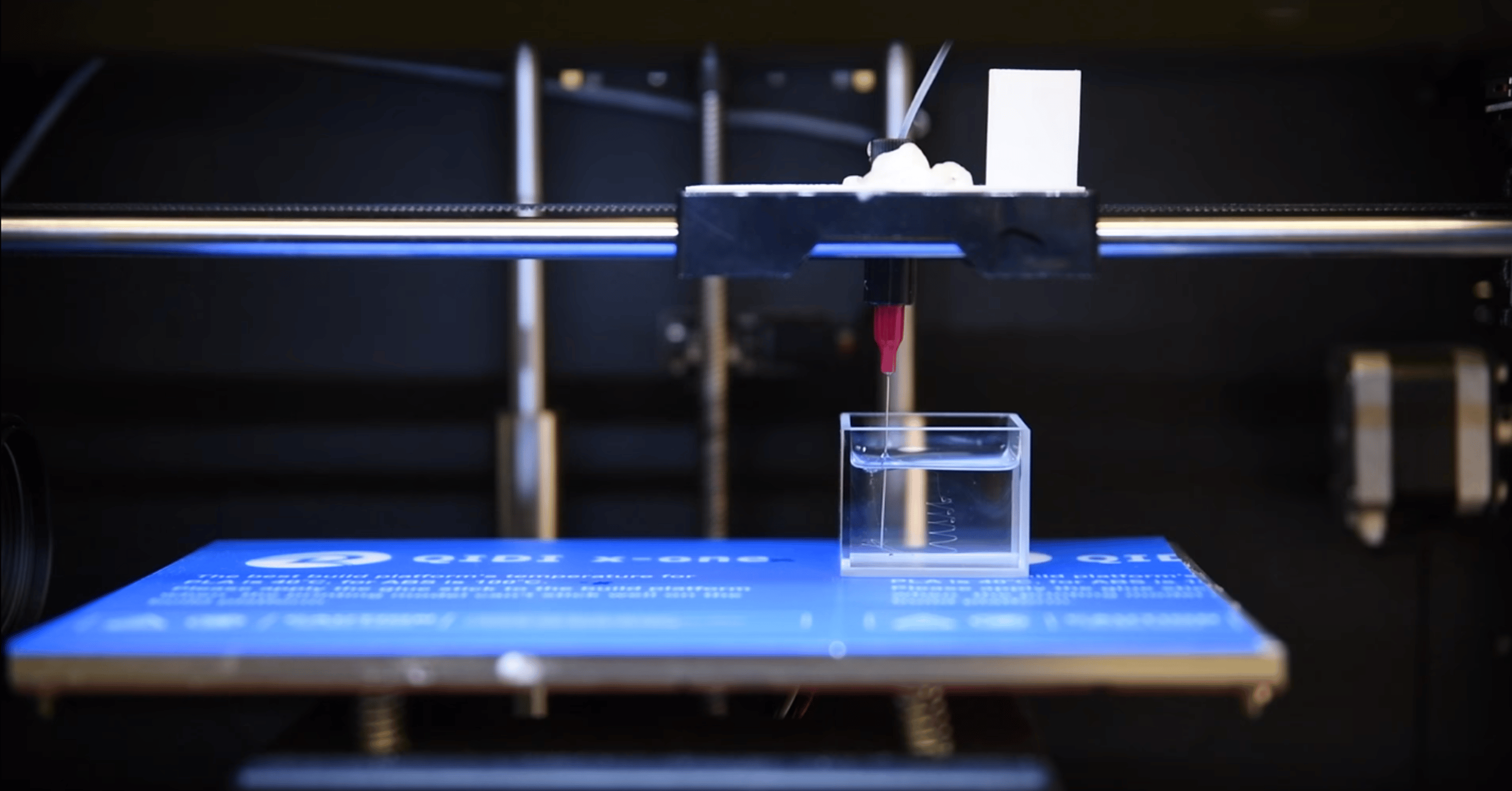

Innovative 3D Printing Method Uses Liquid In Liquid Medium « Fabbaloo

www.fabbaloo.com

Innovative 3D Printing Method Uses Liquid in Liquid Medium « Fabbaloo

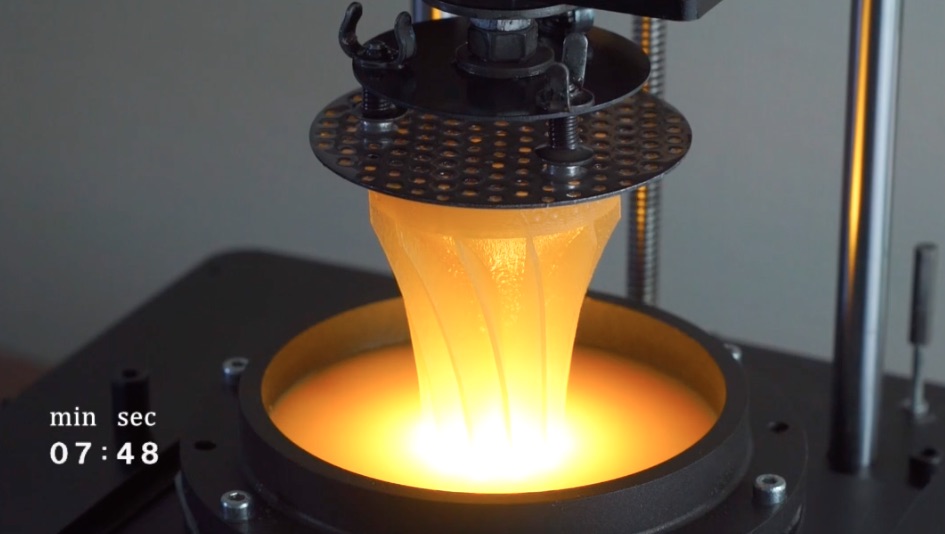

Rapid Liquid Printing Over 3D Printing?

www.eedesignit.com

Rapid liquid printing over 3D printing?

New Rapid Liquid Printing Technique Set To Revolutionize 3D Printing

www.geeky-gadgets.com

New Rapid Liquid Printing technique set to revolutionize 3D printing …

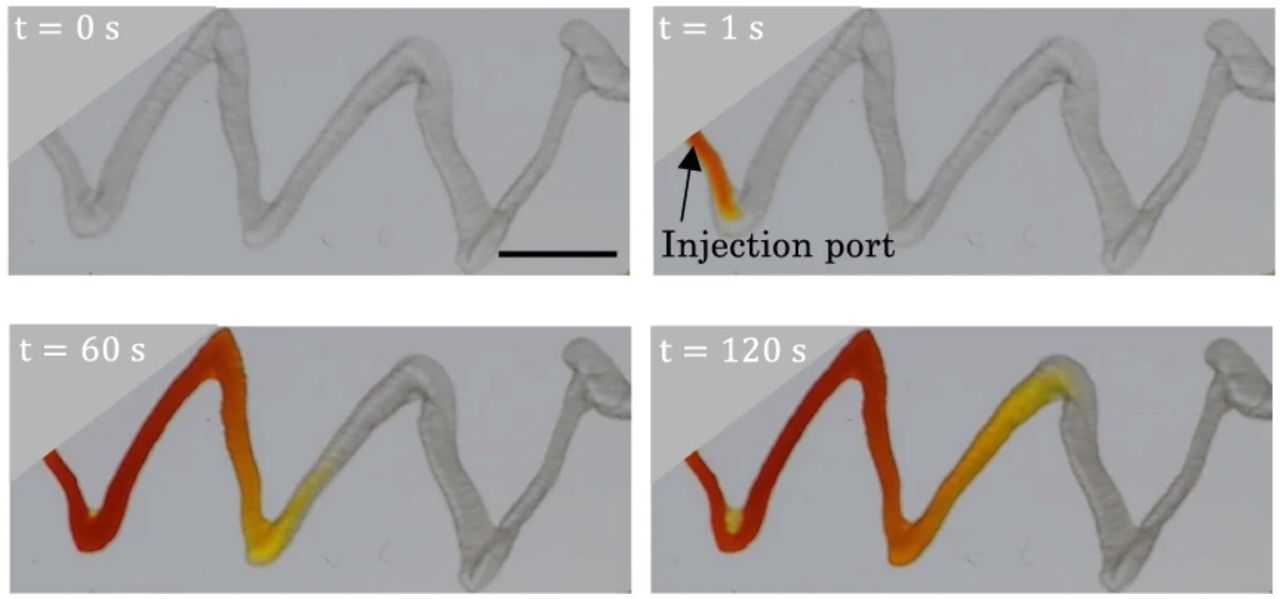

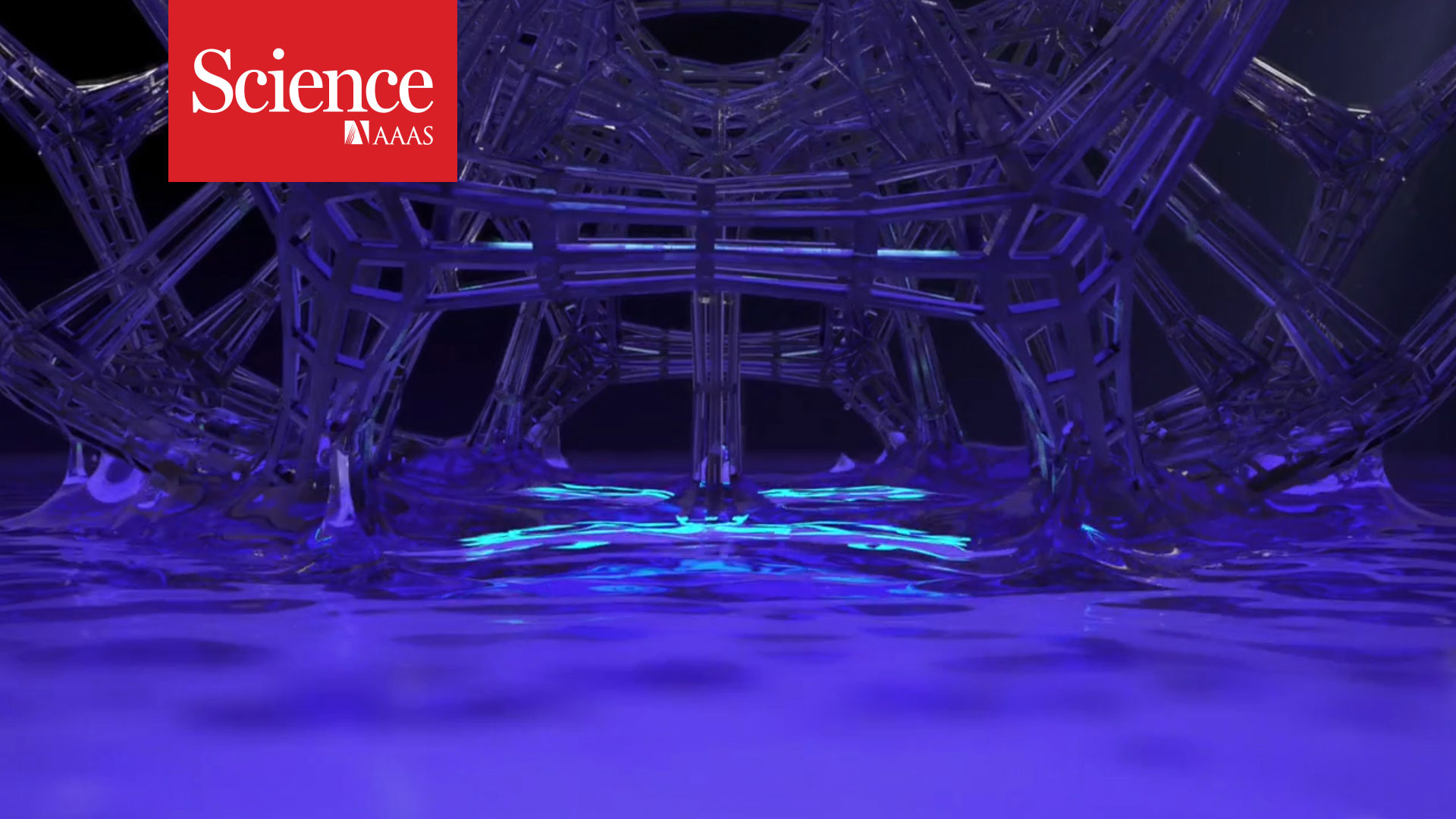

Liquid-in-liquid Printing Method Could Put 3D-printed Organs In Reach

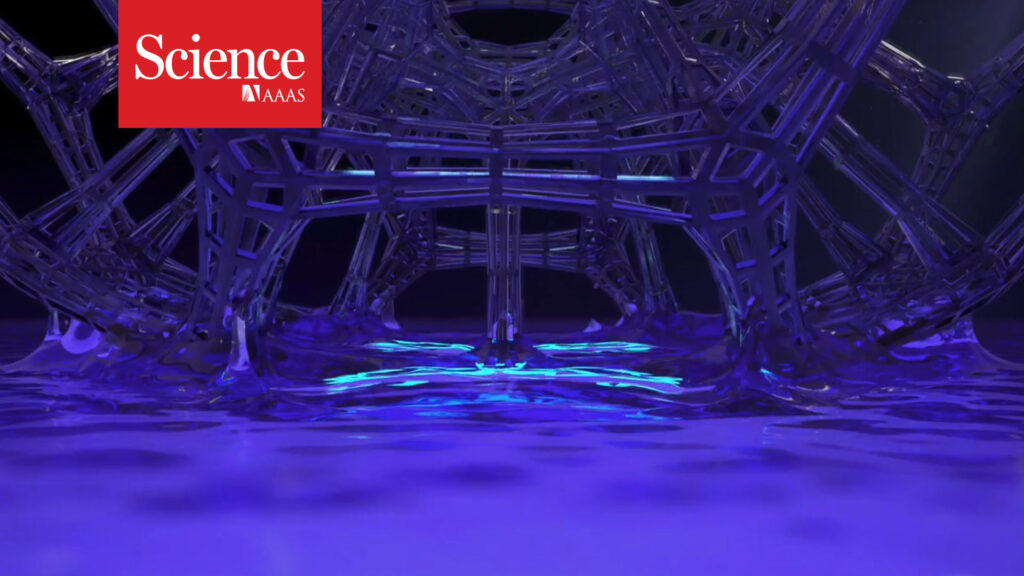

www.science.org

Liquid-in-liquid printing method could put 3D-printed organs in reach …

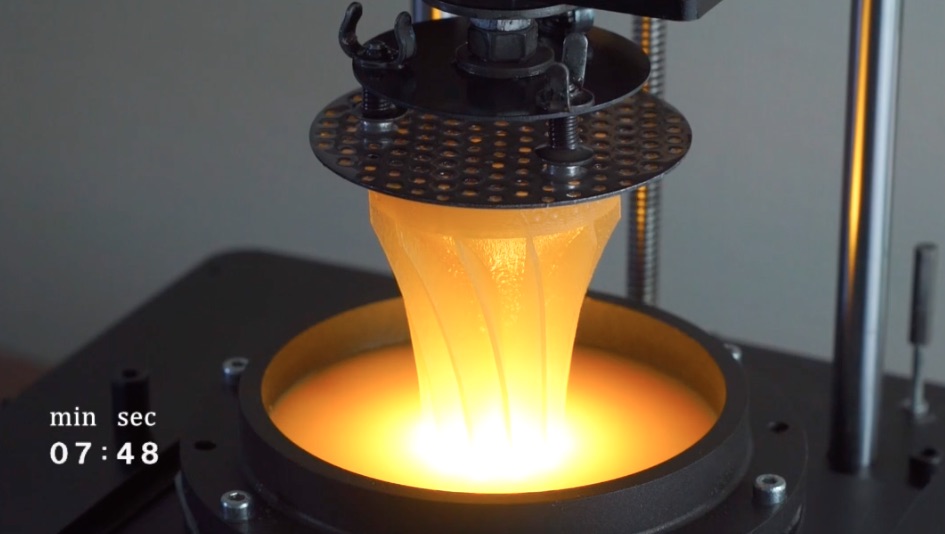

Rapid Liquid-metal 3D-printing Process Produces Large Parts In Minutes

newatlas.com

Rapid liquid-metal 3D-printing process produces large parts in minutes

Rapid Liquid Printing Will Revolutionize 3D Printing | This 3D Liquid

www.facebook.com

Rapid Liquid Printing Will Revolutionize 3D Printing | This 3D liquid …

MIT Researchers Present Rapid Liquid Printing – 3D Printing

3dprinting.com

MIT Researchers Present Rapid Liquid Printing – 3D Printing

3D Printing Is Yesterday's News. Rapid Liquid Printing Is The Future

www.wired.co.uk

3D printing is yesterday's news. Rapid liquid printing is the future …

Liquid 3D Printing Explained | Science | AAAS

www.science.org

Liquid 3D printing explained | Science | AAAS

Innovative 3d printing method uses liquid in liquid medium « fabbaloo. Mit researchers present rapid liquid printing. 3d printing is yesterday's news. rapid liquid printing is the future

:max_bytes(150000):strip_icc()/008_how-to-factory-reset-a-lenovo-laptop-5115817-a67348722ce94f9783881ea29e596310.jpg)