The world of aviation is constantly evolving, and one of the most exciting developments is the increasing use of 3D printing in aircraft design and manufacturing. This innovative technology is revolutionizing the way we build and maintain aircraft, offering a range of benefits from cost reduction to improved performance.

3D Printing: A Game Changer for Aircraft Manufacturing

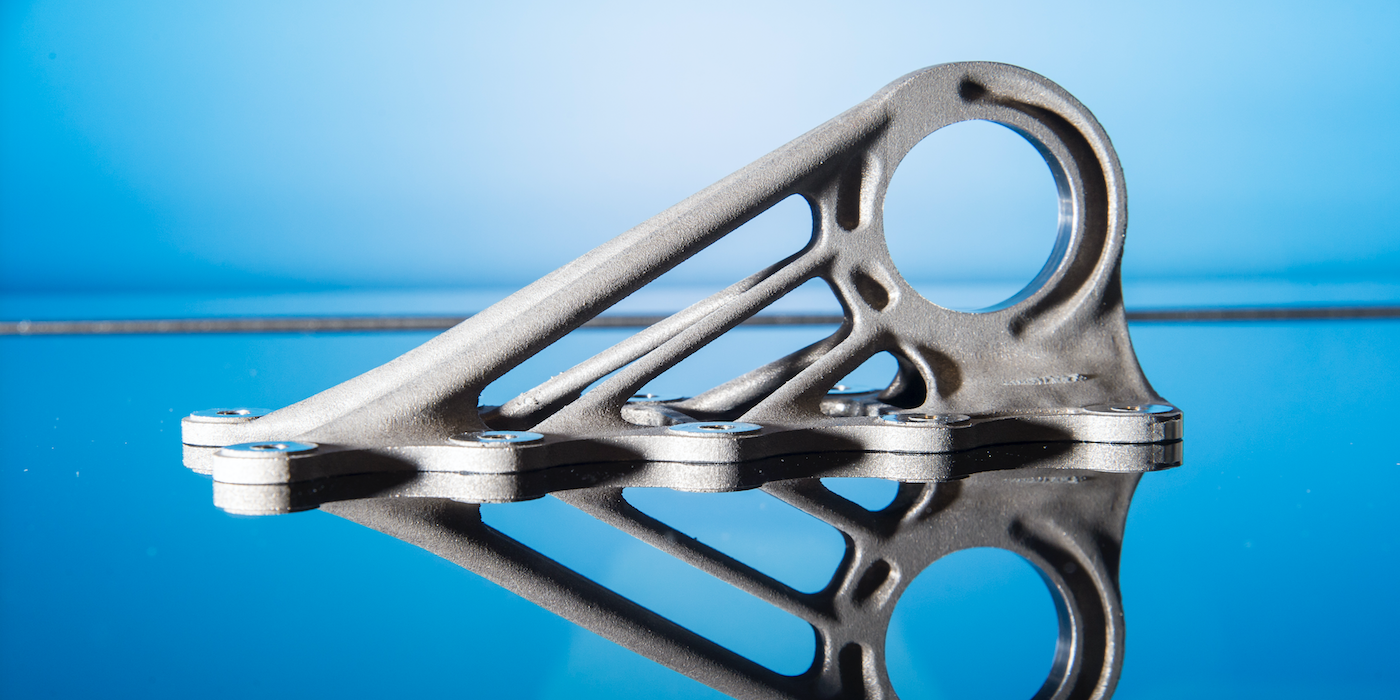

Imagine a world where aircraft parts can be produced on demand, customized to specific needs, and manufactured with unprecedented speed and precision. That’s the promise of 3D printing in the aerospace industry. By using materials like titanium, aluminum, and specialized plastics, engineers can create complex components with intricate geometries that were previously impossible to manufacture using traditional methods.

This has significant implications for the entire aircraft lifecycle. During the design phase, 3D printing allows for rapid prototyping, enabling engineers to quickly iterate on designs and test different configurations. This reduces development time and costs, leading to faster innovation cycles. Once the aircraft is in service, 3D printed spare parts can be produced on demand, eliminating the need for large inventories and reducing downtime. This is particularly beneficial for older aircraft or those operating in remote locations where spare parts may be difficult to obtain.

Moreover, 3D printing enables the creation of lighter and stronger components, leading to improved fuel efficiency and reduced emissions. This is a crucial consideration in an industry that is constantly striving to minimize its environmental impact. The ability to optimize the weight and performance of aircraft components through 3D printing is contributing to a more sustainable future for air travel.

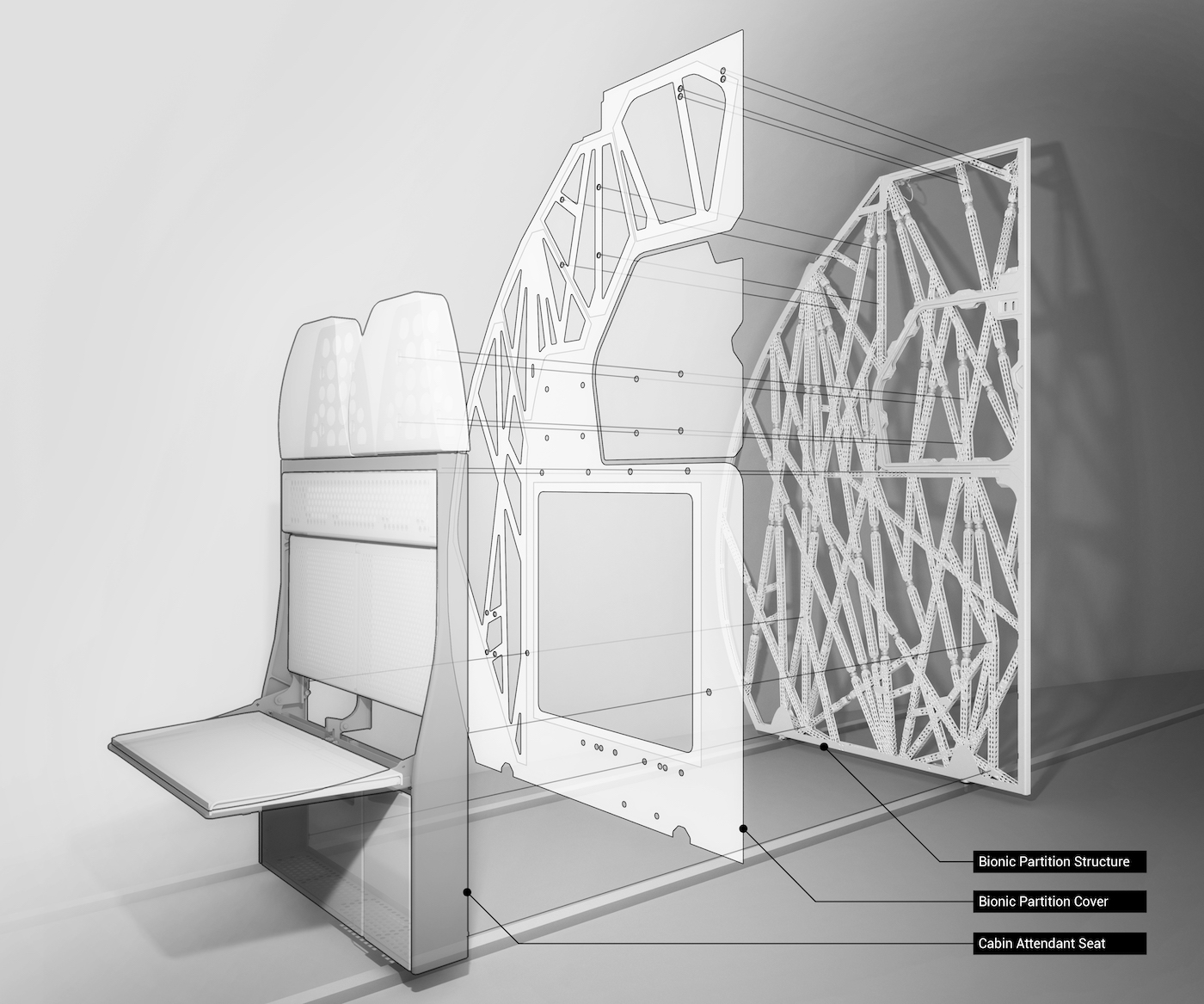

Furthermore, the customization possibilities are virtually limitless. Airlines can tailor aircraft interiors to meet specific passenger needs, creating a more comfortable and enjoyable flying experience. For example, 3D printed seat components can be designed to provide optimal support and ergonomics, while customized lighting and entertainment systems can be integrated seamlessly into the aircraft cabin.

The use of 3D printing also opens up opportunities for enhanced safety features. By incorporating sensors and monitoring systems directly into 3D printed components, engineers can create “smart” parts that provide real-time data on their performance and condition. This allows for predictive maintenance, enabling airlines to identify and address potential problems before they lead to costly repairs or safety issues.

The benefits extend beyond large commercial aircraft. 3D printing is also transforming the design and manufacturing of smaller aircraft, drones, and even spacecraft. Its versatility and adaptability make it a valuable tool for a wide range of applications in the aerospace sector.

3D Printed Aircraft Models: A Glimpse into the Future

Beyond functional components, 3D printing is also used to create detailed and accurate aircraft models. These models serve a variety of purposes, from marketing and promotional materials to engineering prototypes and educational tools. The level of detail that can be achieved with 3D printing is truly remarkable, allowing for the creation of miniature replicas of aircraft that are virtually indistinguishable from the real thing.

These models can be used to showcase the latest aircraft designs, allowing potential customers to get a close-up look at the features and capabilities of the aircraft. They can also be used in wind tunnel testing to study the aerodynamic properties of different designs. In educational settings, 3D printed aircraft models can provide students with a hands-on learning experience, allowing them to explore the intricacies of aircraft design and engineering.

The affordability and accessibility of 3D printing technology have also made it possible for hobbyists and enthusiasts to create their own custom aircraft models. With a 3D printer and a digital design file, anyone can create a miniature replica of their favorite aircraft. This has fostered a vibrant community of 3D printing enthusiasts who are passionate about aviation.

In conclusion, 3D printing is transforming the aerospace industry in profound ways. From revolutionizing aircraft manufacturing to enabling the creation of detailed aircraft models, this innovative technology is shaping the future of aviation. As 3D printing technology continues to evolve, we can expect to see even more exciting applications emerge in the years to come.

If you are searching about 3D printing aircraft interiors – Aircraft Interiors International you’ve came to the right web. We have 10 Pics about 3D printing aircraft interiors – Aircraft Interiors International like 3D Printing Aircraft Parts – The Flight Blog, 3D printing in aircraft – 3DGence and also China Customized 3D Printing Aircraft Models Suppliers, Manufacturers. Here you go:

3D Printing Aircraft Interiors – Aircraft Interiors International

www.aircraftinteriorsinternational.com

3d aircraft printing printed airbus plastic interiors components cabin brackets bionic predicts entire experimenting fuselage constructed metal an

3D Printing Aircraft Interiors – Aircraft Interiors International

www.aircraftinteriorsinternational.com

aircraft 3d printing interiors partition lighter claimed bionic 30kg current than designs be

3D Printing In Aircraft – 3DGence

3dgence.com

3dgence

How 3D Printing Supports Aircraft Design Education

www.linkedin.com

China Customized 3D Printing Aircraft Models Suppliers, Manufacturers

www.china-3dprinting.com

3d Printing Aircraft Model At ₹ 1000/project In Mumbai

www.indiamart.com

3D Printing Aircraft Parts – The Flight Blog

theflightblog.com

aircraft 3d parts printing military industries teflon

Top 3 Ways 3D Printing Is Transforming Aircraft Development

hlhrapid.com

️ Best 3D Files For 3D Printing Of Planes And Aircrafts — 184 Designs・Cults

cults3d.com

CAD / CAM Individual Designer 3d Printing Aircraft Model At Rs 1000

www.indiamart.com

3d printing aircraft model at ₹ 1000/project in mumbai. 3d printing aircraft interiors. 3d printing aircraft parts

:max_bytes(150000):strip_icc()/008_how-to-factory-reset-a-lenovo-laptop-5115817-a67348722ce94f9783881ea29e596310.jpg)